Carbon-ceramic brakes can substantially improve performance, but they’re also a lot more expensive than conventional brakes. This Engineering Explained video dives into why carbon-ceramic brakes are so expensive, and whether they’re worth the extra cost.

Note that the video is sponsored by Brembo, a major manufacturer of both carbon-ceramic and conventional brakes, and the company’s products serve as props for host Jason Fenske.

One factor in the high cost of carbon-ceramic brakes is materials. Conventional brake rotors are made from iron, which is a lot cheaper than carbon. Because carbon-ceramic rotors generally last longer than conventional rotors, they also get higher-grade fasteners, Fenske noted.

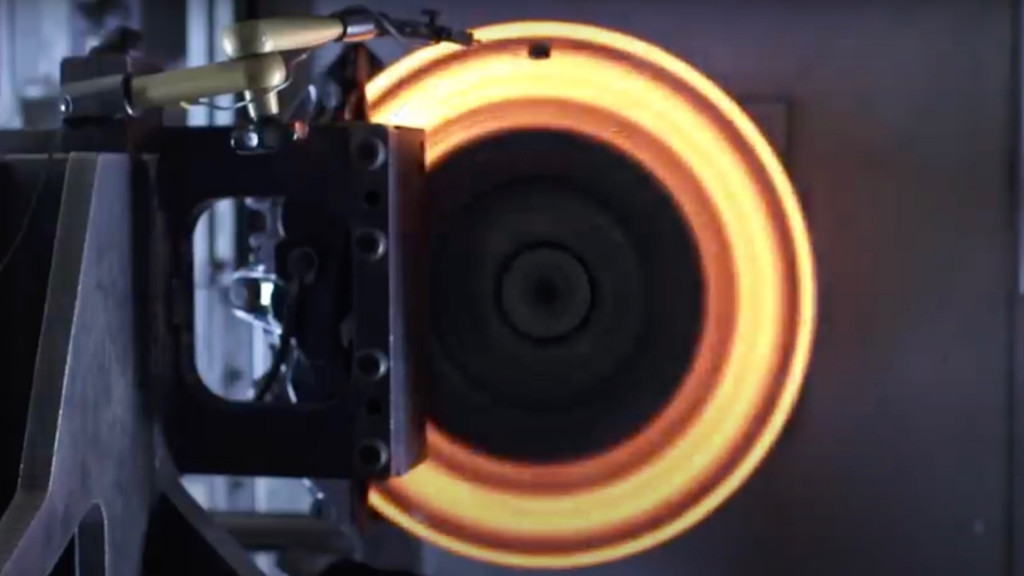

Carbon-ceramic brakes are also a lot more complicated to manufacture. The process takes three weeks, compared to about 90 minutes for a conventional iron rotor, according to Brembo. That’s because the manufacturing process isn’t fully mechanized, and requires some specialized equipment. Carbon ceramics are also a niche product for racing and high-end performance road cars, so they’re sold in low volumes and can’t take advantage of economies of scale.

Carbon ceramic brakes (from Engineering Explained video)

Still, there are some reasons to spend the extra money on carbon-ceramic brakes. They massively reduce brake fade, for example, and weigh less than comparable iron rotors. The iron rotor shown in the video weighs 36.4 pounds while the carbon-ceramic rotor weighs just 16.5 pounds.

That lower weight can have major implications for performance because of where the brakes are located. The rotors spin with the wheel, so cutting their weight reduces rotational inertia, which can improve acceleration times. Reducing the weight of brake components also cuts unsprung mass—the mass not supported by the suspension—which can improve both grip and ride quality.

Carbon-ceramic rotors are also dimensionally stable, meaning they won’t deform at high temperatures and cause brake judder. And because carbon-ceramic brakes have a longer lifespan, owners generally won’t need to replace them during the life of a car, Fenske said. Carbon ceramics’ lower wear rate also reduces brake dust, which can damage wheels and is a source of air pollution.

These advantages are why many automakers have made carbon-ceramic brakes original equipment on their performance models. They’re not a universal solution, though. Ford didn’t use carbon-ceramic rotors for the Mustang Shelby GT500, opting for very large conventional rotors instead, and Porsche has indicated that carbon-ceramic brakes aren’t necessary for track use.